Industrial LCD touch screen: the intelligent engine of production line control system

Industrial LCD touch screen: the intelligent engine of production line control system

In today's rapidly developing Industrial 4.0 era, production line control systems, as core components for optimizing production efficiency and improving product quality, are undergoing unprecedented changes. Among them, industrial touch screens have become an indispensable part of production line control systems with their high efficiency, convenience, and intelligence.

1. Industrial touch screens: a model of intelligent interfaces

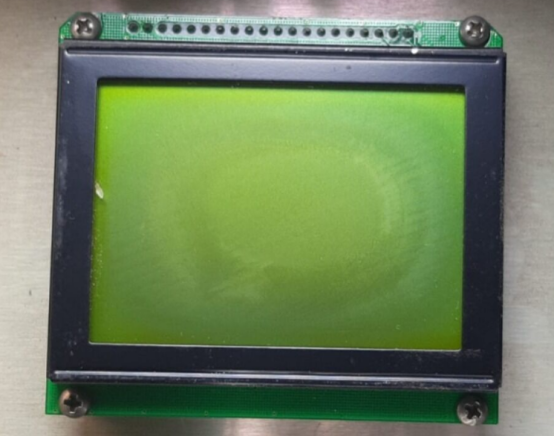

Industrial touch screens, as an intelligent interface that closely connects people and machines through touch-type industrial displays, have completely overturned the operation mode of traditional control buttons and indicator lights. It can not only be used to set parameters, display data, and monitor equipment status, but also vividly depict the automation control process in the form of curves, animations, etc., making the operation more intuitive and convenient.

The industrial touch screen uses advanced touch screen technology, and users can directly click and slide on the screen, which greatly improves the operation efficiency and convenience. At the same time, it has the characteristics of high stability, high reliability, and high durability. It can operate stably in harsh industrial environments to ensure the continuity and stability of the production line.

2. Production line control system: a guarantee of efficient production

The production line control system is a complex system that contains multiple subsystems, each of which has its own unique functions and roles. Among them, the motion control system, visual system, data acquisition system, and control algorithm are the core components.

Motion control system: By controlling servo motors, solenoid valves and other equipment, precise control of workpiece position, speed, acceleration and stop can be achieved.

Vision system: Use high-precision cameras for image acquisition, image processors for image recognition and analysis, and detect product size, shape, color and other parameters.

Data acquisition system: Through sensors installed on machines and controllers, real-time acquisition of temperature, humidity, current, voltage and other parameters, and real-time analysis and processing.

Control algorithm: As the core of the production line control system, adaptive control algorithms such as PID algorithm, Fuzzy algorithm, neural network, etc. are used to monitor various parameters in real time and adjust the production line operation parameters to achieve optimal production efficiency.

As the intelligent engine of the production line control system, industrial touch screens are leading industrial production to a more efficient and intelligent direction. It not only improves the operating efficiency and product quality of the production line, but also reduces maintenance costs, injecting new vitality into the sustainable development of enterprises.

Need dependable LCD screens for your business? Shenzhen Zhiyan Optronics Co., Ltd. offers a full range—from LCD panels to touch displays—with quick turnaround times and factory-direct pricing to support your success.

Comments

Post a Comment