Key Features of Industrial LCD Panels

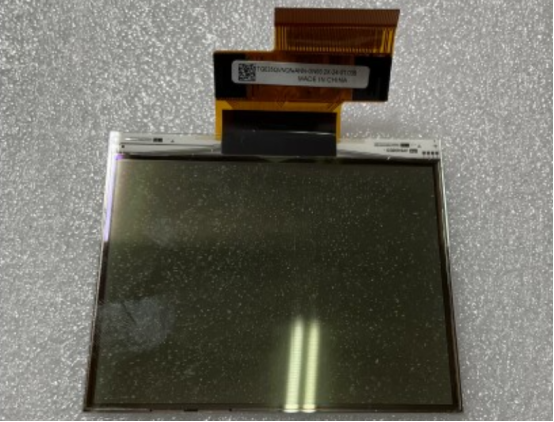

Key Features of Industrial LCD Panels 1. Ruggedized Construction : Reinforced glass or polycarbonate front panels resist scratches, impacts, and chemical exposure. IP65/IP67-rated enclosures protect against dust, water jets, and temporary submersion. Wide operating temperature ranges (-20°C to +70°C) ensure reliability in freezing or scorching environments. 2. Enhanced Visibility & Readability : High-brightness TFT LCD display modules (up to 1,500 nits) combat glare from direct sunlight. Anti-glare & anti-reflective coatings reduce reflections, improving visibility in bright conditions. Wide viewing angles (178°) maintain clarity from multiple perspectives, crucial for control rooms and factory floors. 3. Longevity & Low Maintenance : 50,000+ hour LED backlight lifespans minimize downtime and replacement costs. Fanless cooling systems prevent dust buildup and mechanical failures. Resistant to UV radiation, salt fog, and oil exposure, ideal for marine, mining, and oil & ...