Three characteristics of industrial control LCD screen

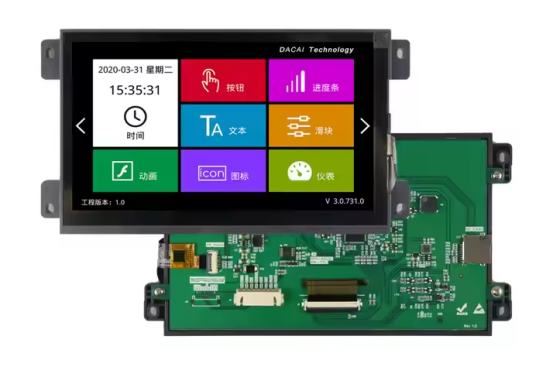

Three characteristics of industrial control LCD screen When it comes to LCD screens, everyone must be familiar with them, but when it comes to industrial control LCD screens, you may not have come into contact with them. With the continuous development of industry, traditional ordinary LCD screens cannot meet the requirements of the industrial industry, so industrial control LCD screens have appeared. Today, the editor will take you to understand the characteristics of industrial control LCD screens. 1. Industrial control LCD screens have high definition The industrial control LCD screen is carefully designed, including a multi-layer structure, and its image quality should be better. For example, it uses an industrial control LED backlight high-definition LCD screen. The indoor color is still excellent, making the industrial control LCD screen display better. 2. Industrial control LCD screens adapt to harsh environments Industrial control LCD screens are different f...